Factory Planning & Operations Platform (Solo)

Improved workflow transparency and efficiency for 100+ daily users by developing a factory-wide operations platform. Started as an SMT scheduler and expanded to dashboards, KPIs, resource management, time & attendance, visitor tracking and more.

💥 Impact

Adopted factory-wide by 100+ users. Increased accuracy of production data, improved planning visibility, and supported data-driven management decisions.

✨ Highlights

Most rewarding project: I built the tools employees used daily, co-designed features with operators through prototypes and feedback sessions to ensure adoption.

📝 Details

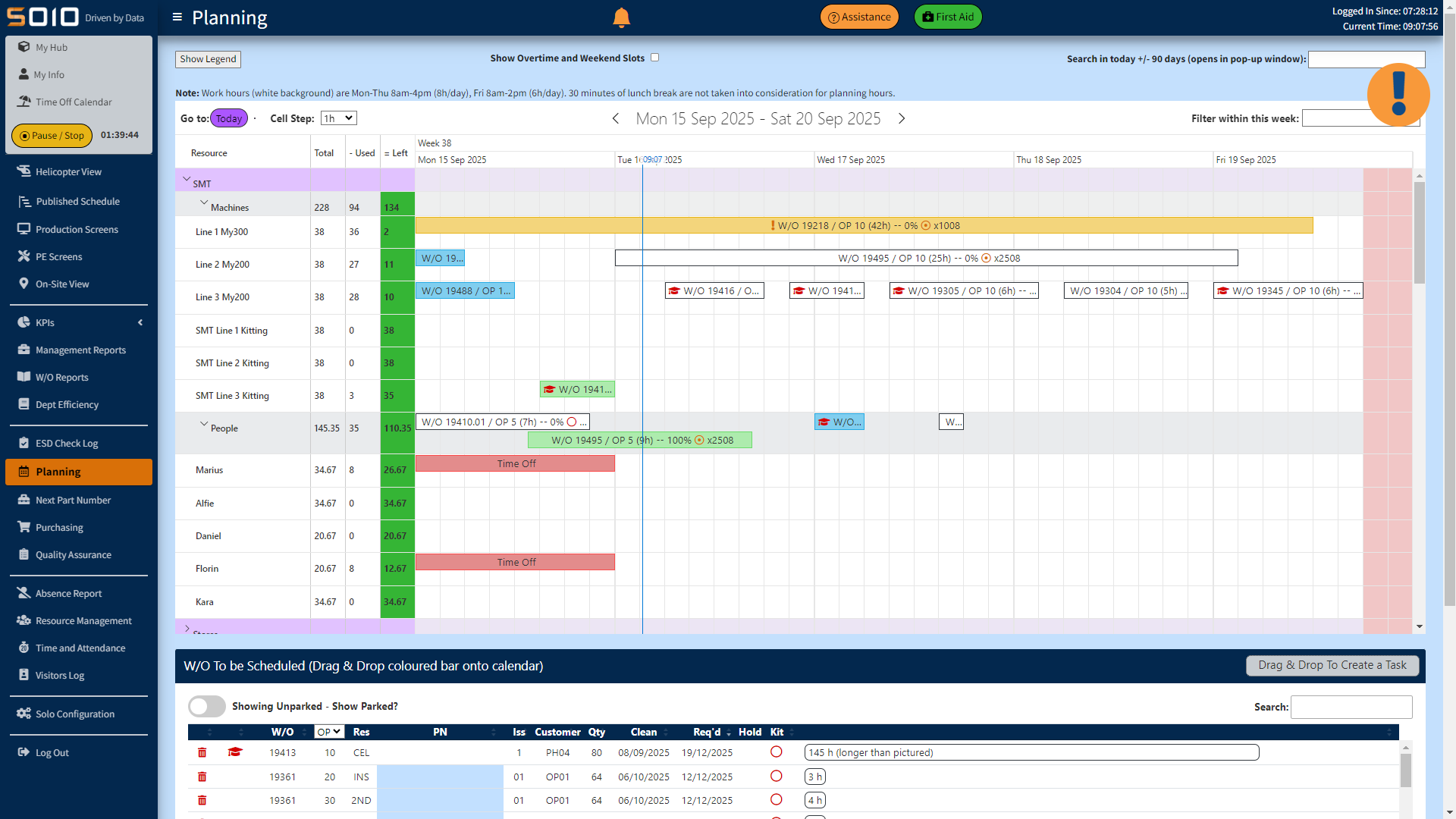

- Started as SMT scheduling tool with drag-and-drop Gantt planning.

- Scaled to all departments with staff shift assignments and resource management.

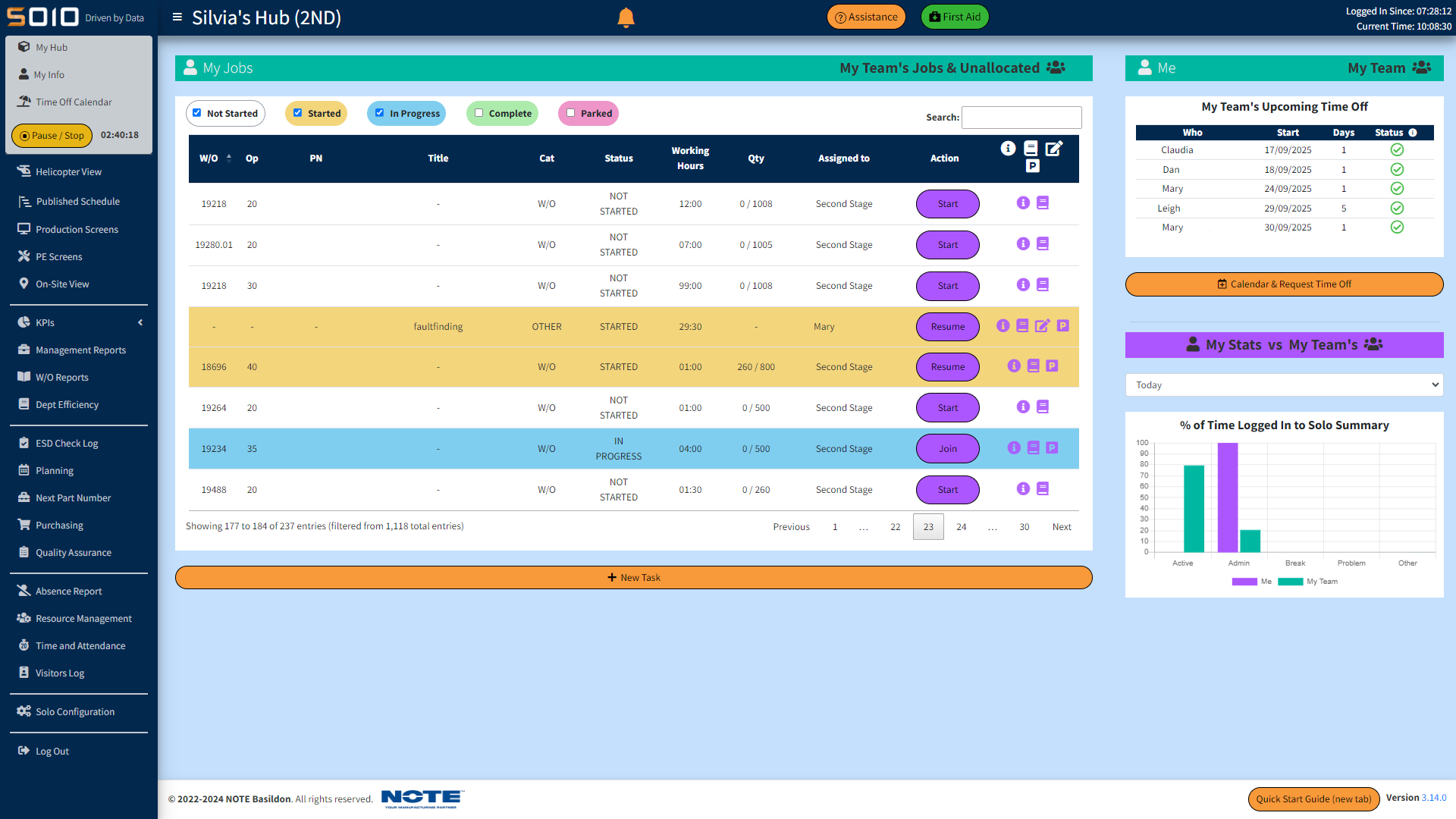

- Operator hub for work packs, job/unit logging, and production visibility.

- Dashboards tracking KPIs, progress vs. planned time, and factory status.

- Time & attendance integrated with door access, occupancy monitoring, and absence workflows.

- Visitor management: pre-registration, sign-in/out, notifications, and access control.

- Additional modules: user management, notifications, and operator assistance requests.

🤝 Contributions

- Led development of the planning module with ERP data import for accurate scheduling.

- Designed and implemented dashboards, resource management, and holiday/absence workflows.

- Built the operator hub with work packs, unit/job tracking, and logging tools.

- Developed visitor management with automated door access integration.

- Created ESD check tablet app with real-time logging and reporting.

- Owned full-stack delivery (frontend, backend, database) across multiple modules.

🗓️ Timeline

Released within a few months and expanded steadily over ~2 years, then placed in maintenance as the company prepared for a new ERP system.

🧑🤝🧑 Team

Worked in a two-developer team with product direction from the operations manager; delivered in agile 2-week sprints.